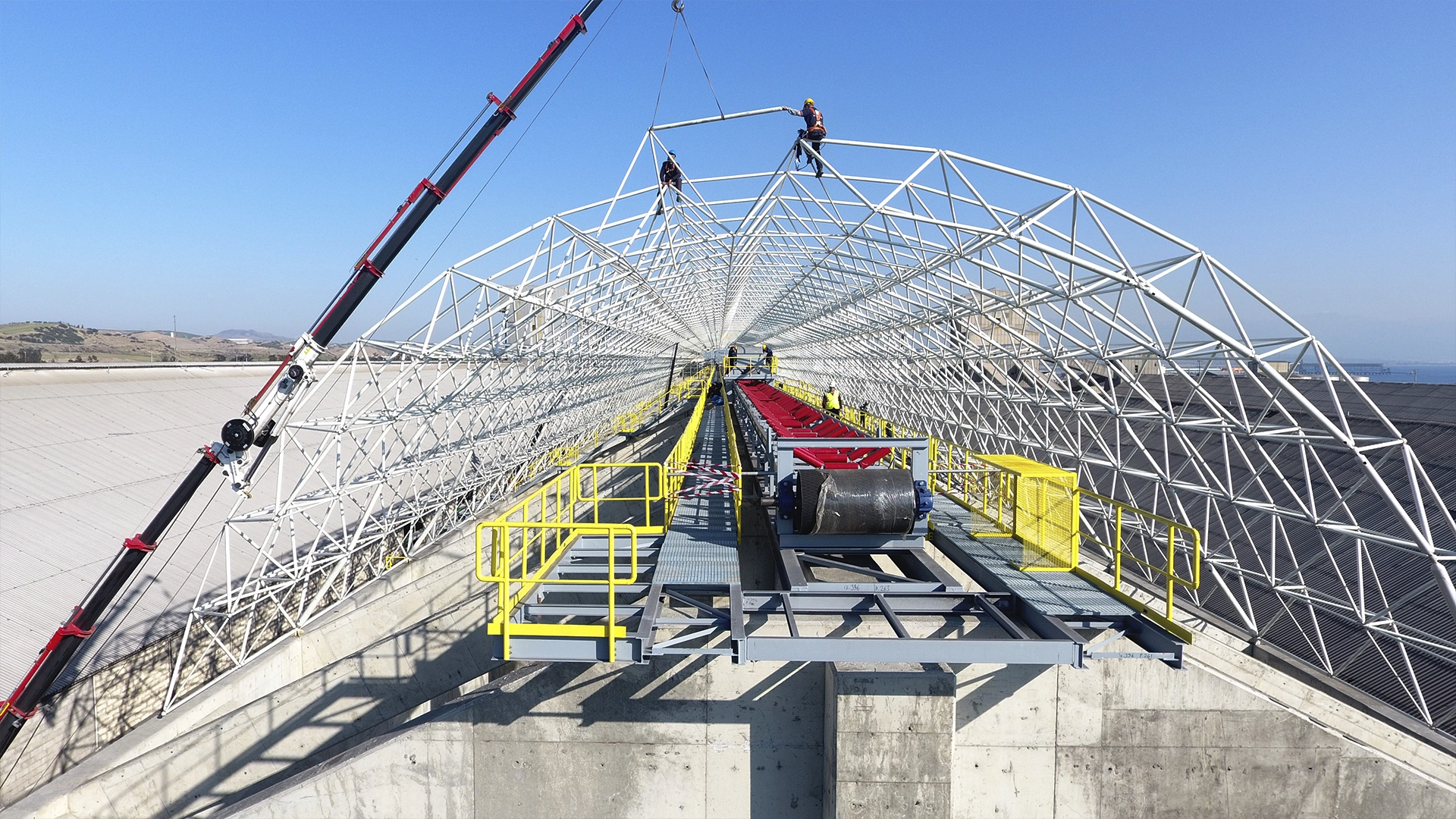

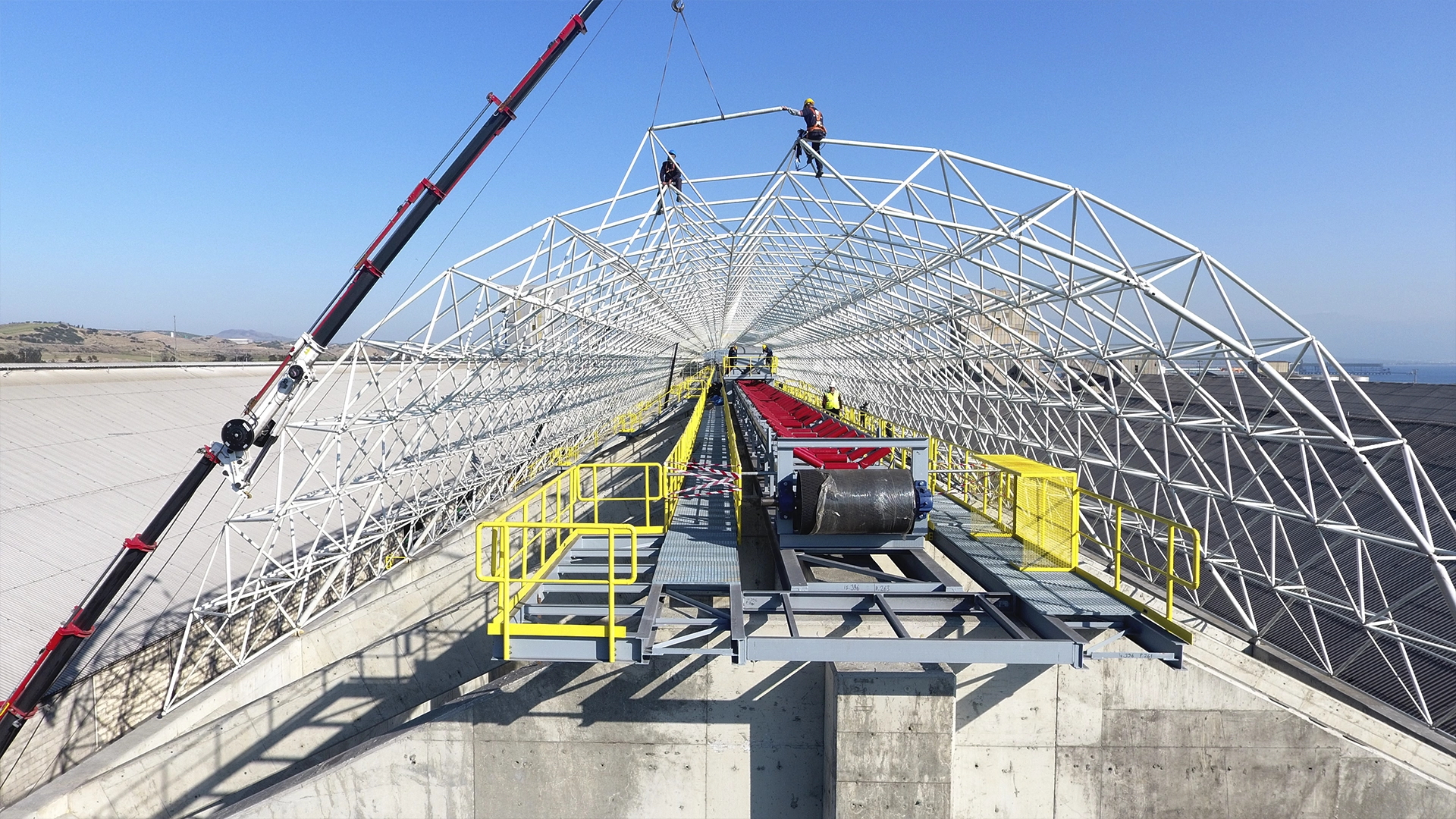

Space frame construction systems are systematic and optimal constructions consisting of steel pipe and node (sphere) elements. These elements provide hyperstatic and exact three-dimensional load distribution, transferring less and balanced load to the load-bearing structure.

POLARKON is responsible for the fabrication of space frame elements using fully automated technology in its own facilities. This process, which is unique to each project, involves the completion of static and architectural design and engineering works for the planned structure. The fabrication of these elements is then monitored from the supply phase to the installation phase.

Advantages of Space Frame Structures

Space frame structures can reduce material usage by up to 40%, making them a cost-effective choice compared to traditional steel designs.

Also, the uniform design of space frames allows for faster fabrication than conventional steel designs because all products are fabricated with numerically controlled machines, which generate much less error.

The space frame’s lightweight structure and uniform elements make it much more efficient to transport than other heavy materials. This leads to significant cost savings in transportation.

At the installation phase, the space frame does not require any welding operations on site under any circumstances, since it is assembled on site with its shoring elements, where installation time reduces the total installation period.

POLARKON is involved in each stage of a project, from its conception to its completion. This comprehensive involvement encompasses design, engineering, procurement, supply, installation, and project management. POLARKON serves as the exclusive point of contact for all aspects of a project, ensuring seamless coordination and execution.